Each of our table tops are hand-made, from scratch, custom created for every client. From raw lumber to a finished table ready for your dinner rush, each is made with a dedication to the details and a love for the craft. Read on to learn the process.

|

1. A top consists of individual wood boards known as staves. We thoughtfully select each piece to create the perfect combination of the patterns in the natural wood grain. |

|

2.The staves are glued together to make an oversized blank panel. At this stage the wood top is ¼” larger on all 4 sides. |

|

3. The oversized blank is then trimmed to its final size, custom for each client. |

|

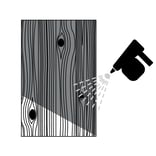

4. We love the natural design our hardwood creates, but to ensure an even surface, any knots are filled with black filler and the top is sanded. |

|

5. Once the table top is created, finish is applied to the raw wood. Clients can select from five standard finishes or customize their own to their exact specifications. |

|

6. After the finish has completely dried, the top is ready to be mounted to the base. Our collection features 10 curated bases, and custom options are always available. |

With over 200 tops created every day, our Wood Shop team of eight is an incredible group of hardworking individuals who exemplify the values and grit of Crow Works. Get to know the team behind the tables.